Driving Leak Detection in RNG: Case Studies from Early Deployments with Maas Energy Works

Introduction

Dairy farms are increasingly adopting anaerobic digesters to capture methane-rich (CH₄) biogas from manure and reduce emissions¹. Maas Energy Works (Maas) is helping lead this effort by converting a dairy byproduct into renewable natural gas (RNG). Maas operates anaerobic digesters that capture CH₄ from manure, creating clean energy from a waste stream.

In August 2024, Maas piloted Qube Technologies’ continuous monitoring system at one site. The results were immediate, enabling on-site operators to identify leaks faster, action quicker repairs, and enhance gas collection volume.

Following the pilot, Maas expanded Qube’s system to 24 additional digesters across California, Texas, and Idaho. The case studies presented here highlight how Maas improved leak response, boosted RNG output, and demonstrated leadership in both environmental performance and operational efficiency.

Case Study 1: Rapid Leak Detection at a Lined Lagoon with Offsite Emissions Sources

Challenge

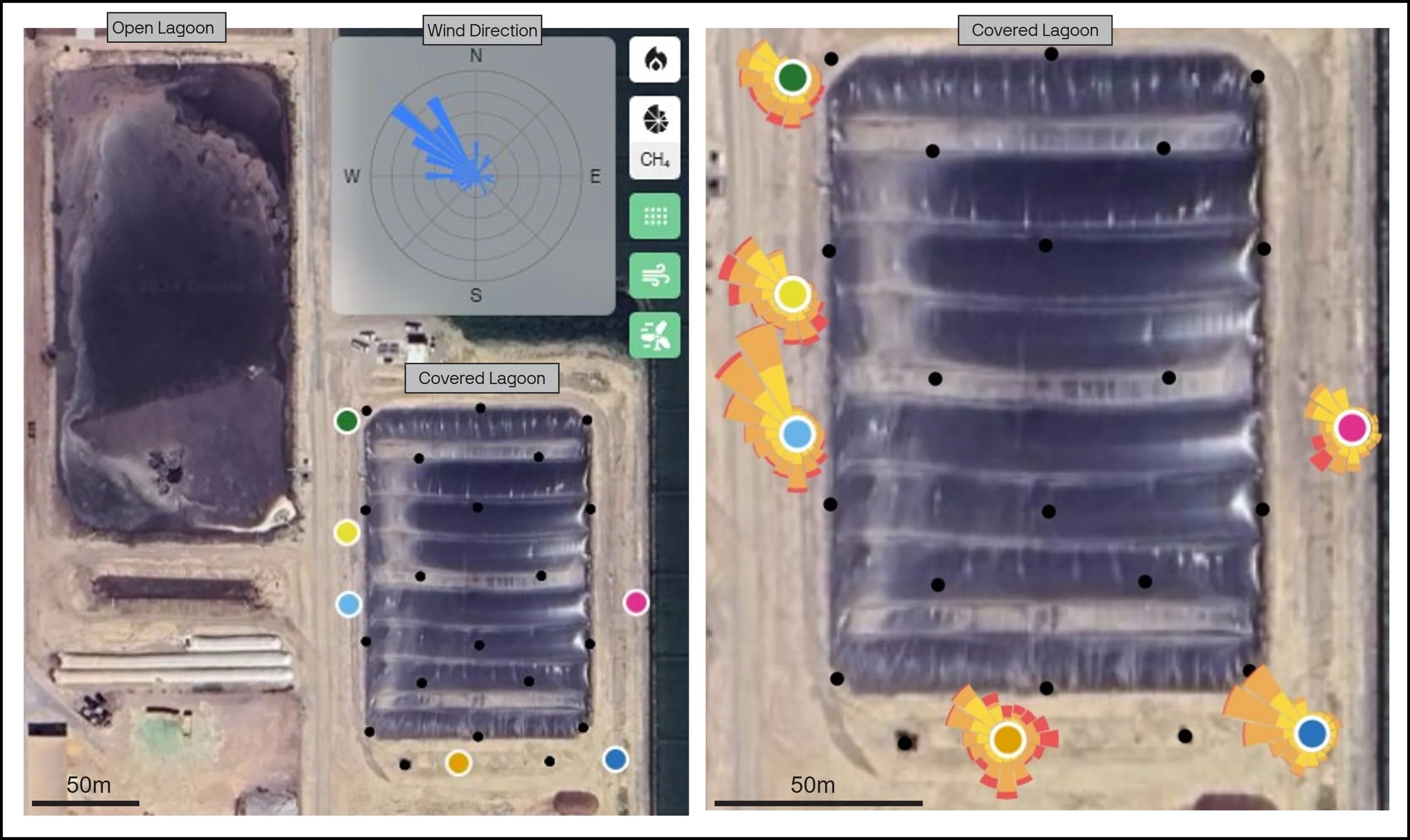

One of the lined lagoons presented a complex monitoring environment due to nearby open manure lagoons. Prevailing northwesterly winds carried methane from an adjacent open lagoon to the digester area, complicating detection efforts (Fig. 1). To add to this, conventional walk-by inspections had been unable to identify any leaks.

Figure 1. Layout of Qube’s continuous monitoring devices (colored circles) at Maas’s dairy lagoon with an open lagoon at the northwest and northwesterly winds (left panel). In the right panel, concentration roses around each device point to methane coming from the open lagoon, indicating prevalent emissions outside the monitored covered lagoon.

Solution

During the deployment planning process, Qube uses historical wind data and knowledge of any offsite sources to generate optimal device placement locations. Once deployed, Qube’s physics-based model uses real-time wind data from anemometers on each device to analyze the direction of any elevated methane readings. This allows the model to filter out any CH₄ coming from offsite sources, ensuring that detections and estimated emission volumes are from actual onsite sources.

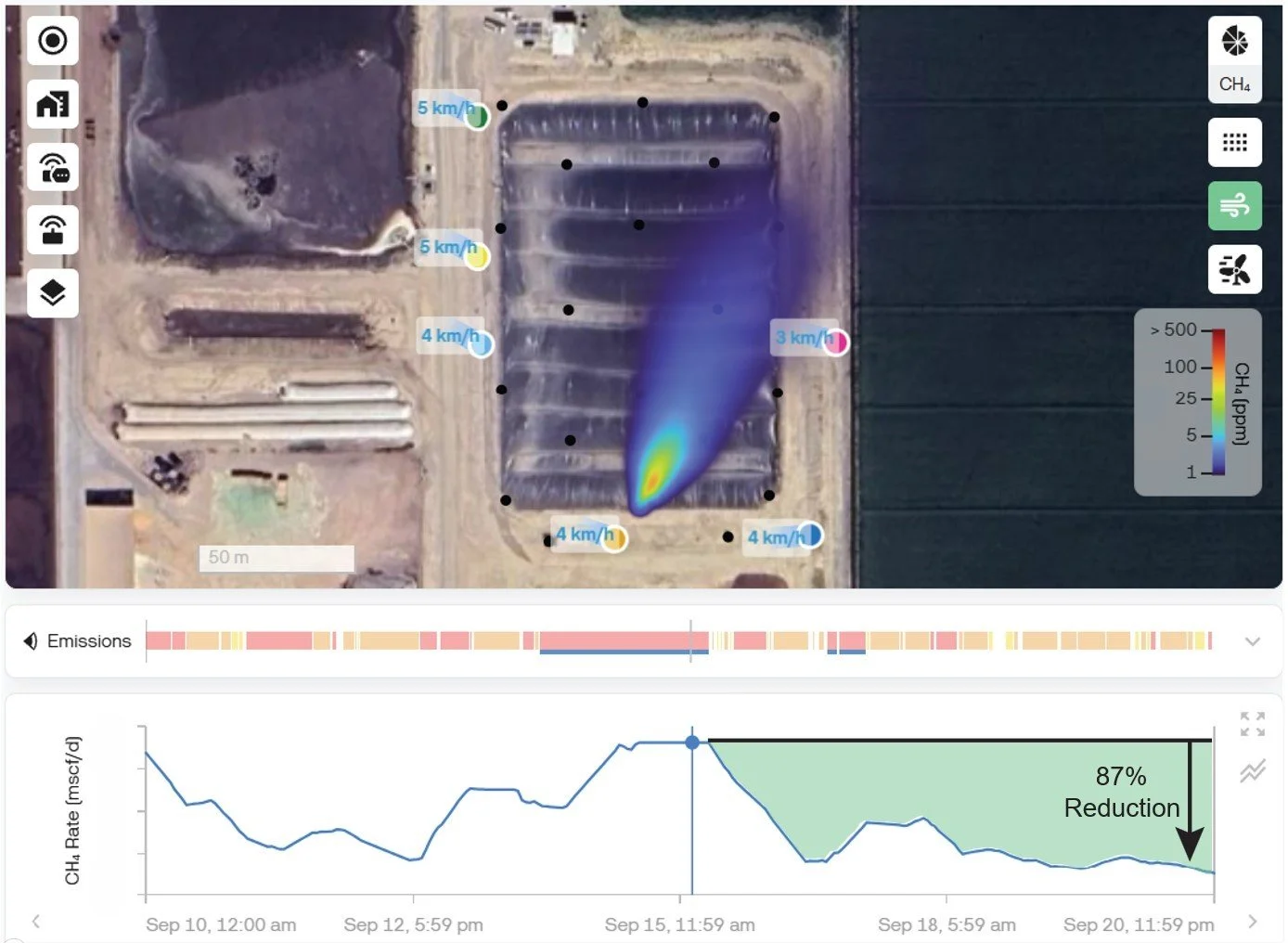

Soon after deploying devices at this lined lagoon, Qube’s system detected persistent emissions coming from an area of the cover that operators had walked by many times without detecting (Fig. 2). After receiving the emission alert from Qube, operators re-examined the area and discovered a broken weld around the sludge port.

Results

This weld was repaired, leading to an 87% decrease in methane emissions. The decrease in measured emissions corresponded directly to increased gas capture, as monthly gas production increased by over 1,000 MMBtu from August to September. This demonstrated a clear example of the win-win nature of continuous monitoring – environmental excellence going hand in hand with business objectives.

Figure 2. Qube’s continuous methane monitoring devices detected persistent methane emissions near the south end of the lagoon cover, visualized via the platform’s simulated plume display. Post-repair monitoring verified a sustained 87% reduction in CH₄ emissions. These results demonstrate Qube’s capability to both detect emission events and confirm the effectiveness of mitigation efforts in real time.

Case Study 2: Unlined Pond with Clay Bottom

Challenge

An unlined pond with a clay bottom means that the outer edge of the top cover must form a tight seal against dirt rather than an HDPE liner, as is the case with most covered lagoons. Qube’s continuous monitoring devices were installed in mid-December and were consistently detecting emissions at these cover seams around the outer edge of the lagoon.

Solution

As these leaks were being diffused through soil rather than releasing from a concentrated point source, the CH₄ concentration was too low to detect with a typical walking survey. The Qube system highlighted the problem areas for the operator to further investigate. The inspection uncovered several areas where the underlying soil was soft and required compaction.

Results

Once the soil in these areas was recompacted, measured emission levels decreased by 67% (Fig. 3).

Reflecting on the first month of the pilot, one of the Maas operators noted:

“Our whole team has been very impressed with the Qube deployment. Many of the leaks the Qube devices have detected were almost impossible to find and required [our operator] to get creative when investigating them.”

Figure 3. Qube’s continuous methane monitoring devices identified small, otherwise undetectable perimeter leaks from uncompacted soil at an unlined lagoon. Using Qube’s real-time data, operators localized and repaired problem areas, reducing methane emissions by 67%, while minimizing inspection time and labor.

Case Study 3: Detecting Leaks in Liner Pocket Vents

Challenge

Less than a month after Qube’s devices were deployed at a lined lagoon, the dashboard signaled elevated emissions from multiple locations along the northwest edge. Operations teams were notified about the emissions by Qube’s automated alerts.

Solution

Upon inspection, the operators confirmed multiple leaks from pocket vents in the liner. The operations team conducted repairs and welded the pocket vents to seal the leaks.

Results

The Qube dashboard verified that the repairs were successful, with emissions steadily decreasing as the pocket vents were welded shut (Fig. 4).

Figure 4. Qube’s continuous methane monitoring devices identified elevated emissions within the first month of deployment, traced to leaking pocket vents in the lagoon liner. Post-repair monitoring confirmed emissions dropped to baseline levels.

What It Means for RNG Operators

Qube’s continuous monitoring solution for RNG lets operators detect and repair leaks as they happen, minimizing emissions and maximizing product retention.

Following a successful pilot on a single site, Maas expanded Qube devices to 24 additional digesters across California, Texas, and Idaho. These deployments have already shown early success as evidenced by the case studies presented here.

You can find more details about this multi-state expansion with Maas in our press release here.

Learn How Qube’s Continuous Monitoring Can Help Your RNG Operations

Interested in real-time leak detection and emissions monitoring for your RNG operations? Get firsthand experience with one of our experts and see how continuous monitoring can protect your assets.

Book a demo with our team today.

Reference

1. Rogriguez, M.V., Rojas Robles, N., Carranza, V., Thiruvenkatachari, R., Reyes, M., Preble, C.V., Pexton, J., Meyer, D., Anderson, R.G., Venkatram, A., Hopkins, F.M. 2025. Anaerobic Digester Installation Significantly Reduces Liquid Manure Management CH4 Emissions at a California Dairy Farm. GCB Bioenergy. 17(7):e70047. https://doi.org/10.1111/gcbb.70047

Explore our other resources and case studies or reach out directly.